THE BRAND: THE JUICERY

THE PRODUCT:

- ORGANA™ - FABRIC TENSION SHAPES & FORMS

TYPE: suspended

INDUSTRY: hospitality – food service

APPLICATION: aesthetic colour treatment

GRAPHICS: full-colour dye-sublimated graphics - printed from supplied artwork

SIZES: various sizes, shapes & forms manufactured to specification on order

LOCATION: Auckland International Airport

OVERVIEW:

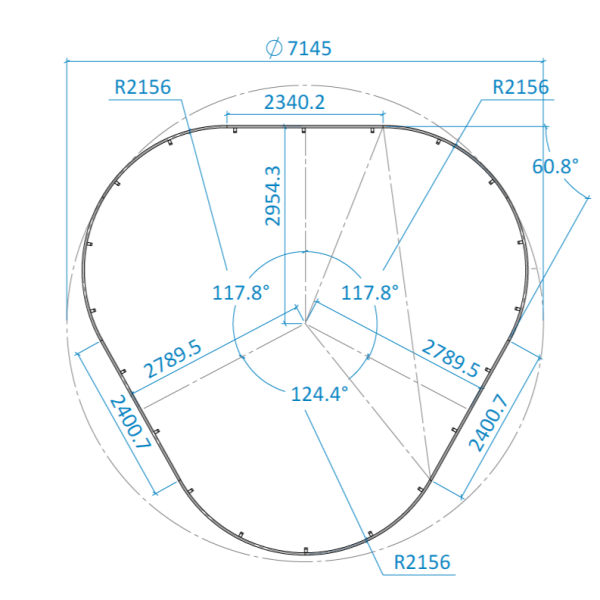

The architectural concept for this project was developed offshore, with OneFrame brought in to resolve the technical execution—transforming the creative vision into a fully engineered, manufacturable, and installable solution. Tasked with bridging the gap between design intent and practical delivery, our team applied its expertise in complex form-making to bring the concept to life.

The organa™ system proved to be the ideal platform for this project. Unlike traditional hardware systems—which are typically constrained by straight lines, hard edges, and fixed angles—organa™ allows for true creative freedom through its ability to form fluid, organic shapes without compromising structural integrity or aesthetic clarity.

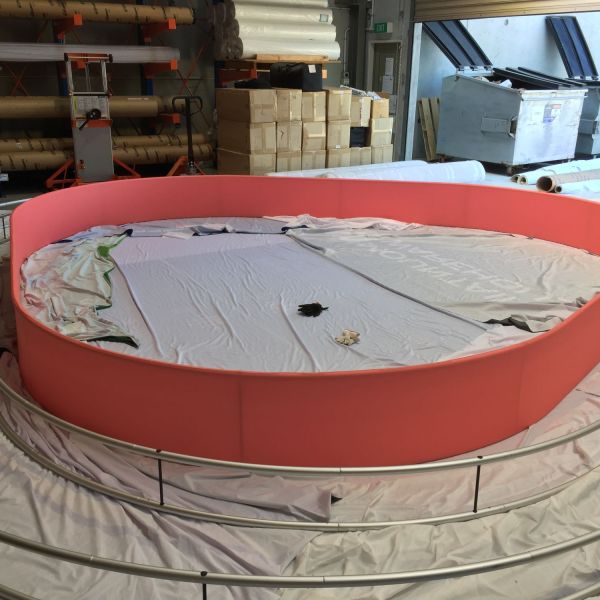

OneFrame’s vertically integrated process allowed us to engineer each element in-house, from precision-rolled aluminium framing to bespoke fabric skinning. Our team not only shaped and fabricated the structural framework to exact specifications, but also digitally printed the fabric membranes to match predetermined colour references—delivering a high-fidelity outcome with perfect alignment to the design brief.

The end result was a series of pre-manufactured, lightweight fabric forms that were delivered to site fully finished and ready to install—minimising on-site disruption and ensuring flawless fitment. This approach offered both design flexibility and commercial practicality, enabling the client to realise an architecturally ambitious concept with a smooth, cost-effective execution.